Accelerated Life Cycle Testing

• Development of Test Plan for the Evaluation of Product or Group of Like Products (A to B Comparison)

• Design and Build Testing Fixture/Power Unit/Test Area

• Executed Life Cycle Test to Test Plan

• Provided Detailed Final Test Report Based on Data Collected

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

• Watertown, SD

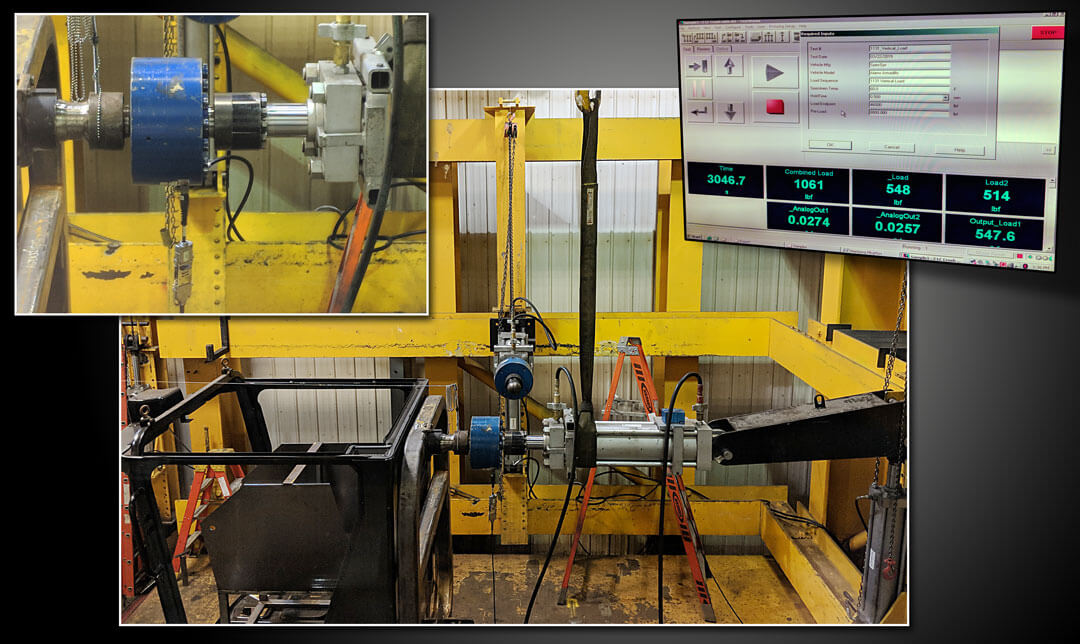

Structural Testing

• Development of Test Plan to Validate Design Analysis

• Prepare Structure for Testing and Data Collection

• Prepare Work Area and Testing Equipment, Perform Test to Test Plan

• Provided Detailed Final Test Report Based on Data Collected

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

• Watertown, SD

ROPS Testing

• Developed ROPS Test Plan Based on Required Industry Standards

• Build ROPS to Analyzed Design

• Conduct Test of ROPS to Test Plan with 3rd Party Vendor

• Provide Detailed Final Test Report Based on Results Provided by 3rd Party Vendor

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

• Watertown, SD

FARO Arm for Validating Parts

The Laser Tracker Measuring Head emits an eye safe laser that is reflected off a Retroreflector target, typically a Spherically Mounted Retroreflector (SMR), back to the Laser Tracker Measuring Head and onto a position sensing detector. The position of the Laser Tracker Measuring Head’s Azimuth and Zenith axis are continually updated using the feedback from this position sensing detector.

• Part Dimension Verification

• Measurement Range of up to 180 feet (55 m)

• Accurate Measurement of the Gravity Vector

• Compact, Lightweight, Quick to Set Up

• Two Rotary Angular Encoders and a Laser-Based Distance Measurement System

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

• Watertown, SD